Product Categories

Liquid Turbine Flow Meter

MODEL: TFM250 Series

CBRO Liquid Turbine Flow Meter is internally developed and perfected by CBRO Instrument. Over the years, CBRO Liquid Turbine Flow Meter has been commissioned in many parts of the world, received praise from end-users and industrial leaders. CBRO Instrument Turbine Flow Meter offers two accuracy classes, 0.5%R and 0.2%R. Its simple structure allows a small pressure loss and virtually no maintenance requirements. Our users can select the preferred converter type depending on the commissioning environment.

Contact us

info@cbroindia.com sales@cbroindia.com

Sales Support

+917021306718

Technical Support

+918591988100

Advantages

Liquid Turbine Flow Meter Advantages and Disadvantages

CBRO strives to provide high-quality products with economical cost.

CBRO Liquid Turbine Flow Meter applies to viscous fluids, non-conductive fluids, solvents, liquefied gases and high-pressure applications.

CBRO Instrument Liquid Turbine Flow Meter provides high accuracy of 0.2% R and a wide range of applications to non-conductive liquids, such as fuel oil, ultrapure water and gasoline. These make the turbine meter more popular compare to Electromagnetic Flow Meter in the oil industry, purifying process and distilleries.

The Flange type connection Turbine Flow Meter is known for its application in oil & gas industry. It is compatibility with high temperature/pressure pipe and high durability makes it the most popular flow instrument in oil and gas industry.

Application

CBRO Instrument Liquid Turbine Flow Meters offers both standard SS304 body and SS316 body. Because of its wide working temperature and pressure range, it is capable of measuring various mediums and commissioning into extreme working conditions.

CBRO Instrument Liquid Flow Turbine Meters are popular in the Oil & Gas industry, Chemical industry, and Water industry. The Flange connection version is compatible with High pressure/temperature commission sites. It is the most popular meter in upstream oil production and transportation, off-shore exploration, water supply, and much more.

Due to its high accuracy and fast response time, CBRO Instrument Liquid Turbine is often integrated into the Industrial Internet of Things, together with valves and pumps to achieve smart process control, for example, solvents batching, blending, storage and off-loading systems. Kindly contact our sales engineers if there are questions related to integrating CBRO Liquid Turbine Meters into your existing plant IOT.

- Measurement/Control

- Batching Application/ Flow rate Comparator (Inlet V/s Outlet)/ Dosing Application.

Application Areas

- Chemical Industries/ Pharmaceutical Industries

- Food & Sugar Industries

- Textile Industries

- Ceramic Industries/ Paper Mills

- Industrial R.O. /Water supply schemes

Various Modes

- Indicator & Totalizer : The meter is in flow indication mode with showing totalizer in display in order to monitor current flow.

- Batcher : Relay will energize after a pressing start button and remains energized till fixed quantity of liquid passes through the sensor. The batcher has a halt and reject batch function.

- Flow Comparator : The meter has two sensors for permeate and reject line. The meter displays both the flow rates and calculates percentage recovery also gives alarm on reducing rate of recovery.

- Rate Switch Mode : The relay has programmed to get energized whenever actual flow falls/rise the set value. Display shows “LOW/HIGHFLOW RATE”. Ideal f or flow interlock, chemical dosing.

- Pulser : To operate specific task on completion of prefix volume. Meter can configure to any metering /dosing pump.

Features

- Each fitting individually calibrated and marked with K factor. (ml/pulse)

- Ceramic ball bearing for superior low flow performance.

- High level (5VDC) signal can be sets up to 100ft. without transmitter.

- For best results we recommend to provide a straight run of 10 and 5D on the upstream and downstream respectively.

- Insertion type sensor also available with solvent cementable adaptors for PVC tees at extra cost.

- Fitting automatically since probe sent at correct depth and orientation.

Important Tips

Electro-magnetic flow meters suffer from the drawback that the flowing media or liquid must be conductive in nature, whereas such is not the case with Turbine Flow meter, which provides excellent performance even in non-conductive liquids like kerosene, petroleum, vegetable oil etc

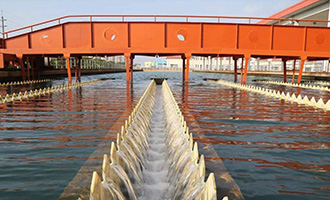

Water Treatment

Petrochemical

Chemical Monitoring

Upstream Oil Transportation

Off-shore Exploration

Water Supply

Technical Data

Table 1: Liquid Turbine Flow Meter Parameters

|

Technical Specifications

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Make

|

CBRO

|

|||||||||

|

Model

|

TFM250 Series

|

|||||||||

|

MEASURING MEDIUM

|

LIQUID

|

|||||||||

|

Size

|

DN15~DN300

|

|||||||||

|

Accuracy

|

±1% (0.5% Optional )

|

|||||||||

|

Repeatability

|

±1%

|

|||||||||

|

Flow Tube

|

SS304 ,SS316

|

|||||||||

|

Rotor

|

SS410

|

|||||||||

|

End Connection

|

Threaded / Tri-clover / Flange End

|

|||||||||

|

Ambient Conditions

|

Medium temperature:-20℃~+150℃; Atmospheric pressure:86Kpa~106Kpa Ambient temperature:-20℃~+60℃; Relative humidity:5%~90%

|

|||||||||

|

Display

|

16 x 2 LCD Flow Rate & Totaliser

|

|||||||||

|

Signal Output

|

Pulse, 4-20mA

|

|||||||||

|

Digital Communication

|

RS485, HART

|

|||||||||

|

Modes

|

Batcher, Flow Comparator, Rate Switch Mode and Pulsar

|

|||||||||

|

Power Supply

|

230VAC/24V DC/3.6V Lithium Battery

|

|||||||||

|

Cable Entry

|

M20*1.5; 1/2"NPT

|

|||||||||

|

Explosion-proof class

|

Flameproof Explosion Proof CMRI IIA IIB, ( ATEX / PESO Enclosure Optional )

|

|||||||||

|

Protection class

|

IP65

|

|||||||||

|

Mounting

|

In-Line Horizontal / Vertical

|

|||||||||

Installation

Before the installation, it is crucial to communicate with our sales engineers regarding the working conditions and medium the meter designs to measure.

The installation of the Q&T Flange Type Liquid Turbine Flow Meter involves minimal effort. During installation, the users will need bolts, nuts, washers and appropriate tools for installation.

The user needs to keep in mind these three factors while carrying out the installation.

1. There should be at least ten pipe diameter lengths of straight pipe upstream of the Turbine Meter and five pipe diameter length of straight pipe length downstream of the Turbine Meter, with the same nominal diameter size.

2. Valves and Throttling devices needed to install downstream of the flow meter.

3. The arrow indicated on the meter body is the same as the actual flow.

If there are specific questions regarding the installation of the Q&T Instrument Turbine Meter, kindly contact our sales engineers for assistance.

.jpg) One 90° elbow | .jpg) Two 90° elbows for two planes |

.jpg) Concentric expander | .jpg) Control valve half-open |

.jpg) Concentric shrinkage wide open valve | .jpg) Two 90° elbows for one plane |

Q&T Liquid Turbine Flow Meter requires minimum maintenance

Cleaning and inspection of flow meter can be carried out by remove the Turbine Meter from the pipe.

Reinstallations are carried out similarly to the installation steps indicated above.

If the meter is damaged and repair is needed, kindly contact Q&T Instrument Sales Engineers.

Other Products in 'Turbine Flow Meter' category

SEND YOUR INQUIRY

Exported to more than 150 countries around the globe, 10000 sets/month production capacity!